Automated Equipment for Inspection

All Sence Wall-climbing Structural Quality Detection Robot

As a new tool for underground engineering inspection, the All Sence Wall-climbing Structural Quality Detection Robot adopts advanced negative pressure adsorption technology to move freely on various vertical surfaces (e.g., concrete, glass, metal) and cover high-risk hidden areas on-site, and is equipped with an automated mechanical inspection device to perform non-destructive testing on internal structural defects such as cavities and delaminations and display results through imaging, facilitating comprehensive and safe on-site inspection work.

All Sence Wall-climbing Rebar Detection Robot

As a new tool for pier and high-tower engineering inspection, the All Sence Wall-climbing Rebar Detection Robot adopts advanced negative pressure adsorption technology to move freely on various vertical surfaces (e.g., concrete, glass, metal) and cover high-risk hidden areas on-site, and is equipped with an electromagnetic wave detection module and a wireless communication module to scan the position of steel bars and the thickness of protective layers at high-risk locations and synchronously display the detection information to the operator, facilitating comprehensive and safe on-site inspection work.

All Sence Wall-climbing Patrol Robot

As a new tool in the inspection industry, the All Sence Wall-climbing Patrol Robot adopts advanced negative pressure adsorption technology, enabling it to move freely on various vertical surfaces (e.g., concrete, glass, metal) and cover high-risk hidden areas on-site. Equipped with an industrial-grade camera, it can transmit high-definition images in real time, detect and record surface defects in the inspection area, and provide functions for image information classification, marking and statistics—facilitating comprehensive and efficient on-site inspection and maintenance work.

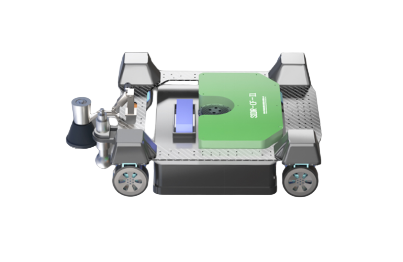

Intelligent Detection Robot

The intelligent inspection robot integrates multiple sensor technologies and elastic wave nondestructive testing technology, replacing the traditional manual tapping data collection method with a fully automated robotic system. This significantly reduces the workload of on-site personnel and improves inspection efficiency.

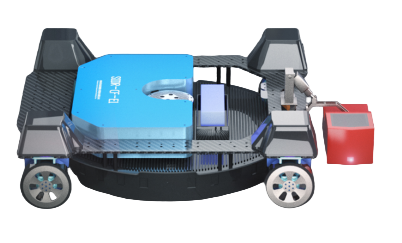

Intelligent Radar Detection Robot

The intelligent radar detection robot adopts multi-sensor fusion technology, enabling automatic cruise detection and precise scanning of designated areas. It can replace technicians in on-road operations, improving efficiency and reducing the burden on personnel.

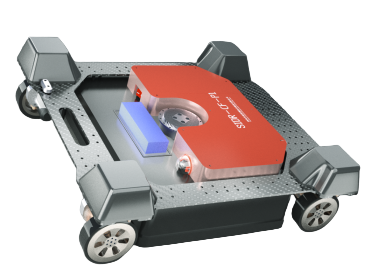

Intelligent Concrete Slab Detection Robot

The intelligent concrete slab detection robot integrates multi-sensor information to enable path setting and automatic detection, conducts comprehensive scanning of designated concrete slabs for internal defect detection (thus reducing inspectors' workload), and adopts imported original components for some of its parts to ensure accurate and fast detection results.

All-Terrain Climbing Tracked Robot

The tracked robot is a specialized load-bearing robot designed for various terrains and environments, which uses tracks as moving components to enable mobile operations in scenarios such as embankments, wild grasslands and deserts, and can be equipped with a ground-penetrating radar system to scan and detect the conditions beneath its travel path (e.g., road surfaces, internal structures of embankments) while traversing mountains and hills.

Intelligent Compaction Simulator Robot

The device employs multi-sensor fusion technology and features a central processing module. It is controlled remotely via a handheld transmitter to perform vibratory rolling operations on specific areas. Additionally, it is capable of conducting intelligent compaction through autonomous path planning within designated zones without requiring manual intervention.

Smart Sentry

The Smart Sentry primarily consists of five components: a 360° camera, network transmission and storage system, pneumatic lifting system, power supply and storage system, and a lightweight mobile chassis. It features easy installation and simple operation.